Email: fern@hotechmachinery.com Tel: +86 13622727078

Stainless steel Decorative Pipe Making Machine is design to produce welded round tubes/square tubes,with diameter 4.8mm-325mm,thickness 0.2mm-6.0mm. The tube mill is newly design based on proactical producing and acquiring the advantages of equipment Taiwan design, which is also convenient in operation and maintenance. Brand: HOTECH Payment:T/T, L/C at sight Product Origin: Foshan, China Lead Time:60 days

Decorative Pipe Mill is a revolutionary machine that elevates the pipe manufacturing process to new heights of creativity and aesthetics. It integrates cutting-edge technology and innovative design to produce decorative pipes that are not only functional but also visually stunning. This tube mill is specifically engineered to meet the demands of designers, architects, and manufacturers seeking to add a touch of elegance and sophistication to their projects.

Steel Pipe/Tube Making Machine can produce steel pipe/tube with ss materials and ms, gi materials such as 316,304,409,3201,202,Q235. our pipe/tube making machine is W forming, in the welding section we will weld the pipe.

Stainless Steel Tube Production Line is used to produce Furniture tube such as chair foot, table foot etc. Construction tube such as Hand railing, Building support tube, Water tube, Chimney tube, Door tube; Industrial tube such as Exhaust tube, NB tube, Condenser pipe, Sanitary tube etc.

| Model | Diameter range | Round pipe thickness range | Square pipe thickness range | Installation size | Material | Capacity |

| S-HG40 | Φ6-Φ31.8 | 0.2-1.2mm | 0.2-0.7mm | 20x1.0 | SS,CS,GI | 1-20m/min |

| HG40 | Φ12.7-Φ50.8 | 0.3-1.5mm | 0.3-1.0mm | 21.5x1.1 | SS,CS,GI | 1-15m/min |

| B-HG40 | Φ12.7-Φ63.5 | 0.3-2.0mm | 0.3-1.5mm | 21.5x1.1 | SS,CS,GI | 1-15m/min |

| HG50 | Φ25.4-Φ76.2 | 0.4-2.5mm | 0.4-2.0mm | 24x1.2 | SS,CS,GI | 1-15m/min |

| HG60 | Φ31.8-Φ101.6 | 0.5-3.0mm | 0.5-2.5mm | 26x1.4 | SS,CS,GI | 1-10m/min |

| B-HG60 | Φ50.8-Φ133 | 0.5-3.0mm | 0.5-2.5mm | 26x1.4 | SS,CS,GI | 1-10m/min |

| HG70 | Φ63.5-Φ168 | 1.0-4.0mm | 1.0-4.0mm | 27x2.0 | SS,CS,GI | 1-10m/min |

| HG80 | Φ88.9-Φ219 | 1.5-5.0mm | 1.5-5.0mm | 28x2.3 | SS,CS,GI | 1-5m/min |

| HG-100 | Φ168–Φ325 | 1.5-6.0mm | 1.5-6.0mm | 42x4.0 | SS,CS,GI | 1-5m/min |

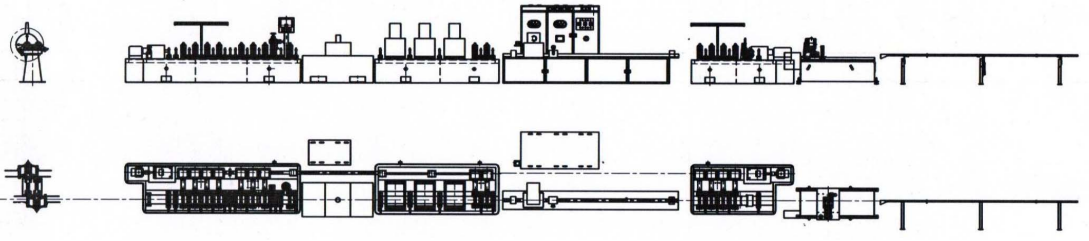

Machine Processing: Un-coiler→ Forming Section→ Welding Section→ Grinding Section→ Sizing & Straightening Section→ Cutting Section→ Run out table

| Machine Paramter | |

| Major motor | Siemens |

| Reducer | NJ130 or Dongfeng 145 |

| Cutting machine | Abrasive Cutting Machine or Metal saw cutting machine |

| Welding device | Included |

| Machine base | Q235 materials |

| Machine shaft | 40Cr |

| Machine arrangement | 3-3-1-4 or 4-4-1-4 |

| Customized Design | |

| PLC control system | Optional |

| Roller bearing standd design | Optional |

| Grinding section | Manual / Semi-automatic / Fully automatic |

| Double Motor | Optional |

| PLC control cutting machine-cut short pipe below 1 meter | Optional |

| Double acting system | Optional |

| Online inside bead rolling machine | Optional |

| Online bright annealing machine | Optional |

| After Sale Service | |

| Warranty time | 1 year |

| Installation service | 15 years experience engineer base on salary |

| Factory layout drawing | Provide |

| Return visit service | 2-3 times per month |

| Field visit service | 2-3 times for mature market |

Steel Pipe Tube Manufacturing Machine characteristic:

1. The whole SS Pipe Mill machine is welded by Q235 steel plate, world's top five hundred BAOSTEEL material ,machine vibration aging treatment.

2. Follow Taiwan technology, provide stable structure design.

3. All the key parts are processing by CNC machine centre to ensure the precision of equipment .

4. Adopt NJ130/Dong Feng auto transmission, enhanced turbine gearboxes ,ensure stability of transmission system.

5. SS Pipe Machine can be customized by customer's requirements.

Tube Manufacturing Machine Advantages

1. Advanced Pipe Rolling Machine for Decorative Purposes: The tube mill machine boasts an advanced pipe rolling machine that allows for intricate and precise designs to be effortlessly incorporated into the pipes. This tube making machine is equipped with state-of-the-art software and controls, enabling the creation of captivating patterns, textures, and motifs on the surface of the pipes.

2. Versatile Tube Milling Machine: The Pipe Mill Machinery also includes a versatile tube milling machine, which ensures seamless precision and accuracy during the manufacturing process. This machine can handle various pipe sizes and shapes, allowing for customization and flexibility in design.

3. Stainless Steel (SS) Pipe Machine: The Decorative Pipe Mill features a dedicated SS pipe machine, engineered specifically to work with stainless steel. This SS Tube Machine guarantees the durability, strength, and corrosion resistance required for long-lasting and high-quality decorative pipes.

4. Automated Operation and Control: Our decorative tube manufacturing machine is designed for efficient and user-friendly operation. It incorporates automated features and intuitive controls, reducing manual labor and ensuring consistent output. This allows operators to focus on unleashing their creativity while maintaining optimal production efficiency.

5. Quality Assurance Systems: The ss tube mill machine includes robust quality assurance systems to maintain the highest standards of pipe production. These systems monitor and control parameters such as wall thickness, diameter, and surface finish, ensuring that every decorative pipe meets the desired specifications.

Decorative Pipe Mill Advantages

1. Architectural Design: The Steel Pipe Machine enables architects to incorporate decorative pipes into building facades, interior designs, and landscape projects. These pipes can be used as handrails, balustrades, decorative columns, and more, adding a touch of sophistication to any architectural masterpiece.

2. Furniture Manufacturing: The Decorative Pipe Mill offers furniture manufacturers the opportunity to create unique and eye-catching designs. Decorative pipes can be used as chair frames, table legs, bed frames, and other furniture components, allowing for the infusion of artistry and functionality.

3. Interior Design: Interior designers can incorporate decorative pipes into lighting fixtures, room dividers, handrails, and other elements of interior spaces. These pipes can serve as focal points, adding a touch of elegance and uniqueness to residential and commercial projects.

4. Event Decor: The tube mill from Hotech offers event planners and decorators the opportunity to create captivating and stylish event setups. Decorative pipes can be used as stands for floral arrangements, backdrops, signage, and more, making any event truly memorable.

Loading Pipe Machine Picture for Shipment

Tube mirror polishing machines utilize a combina

Tube forming machines are essential equipment in

Seamless pipe is manufactured by extruding the m

Contact: Fern Li

Phone: +86 13622727078

Tel: +86 13622727078

Email: fern@hotechmachinery.com

Add: Shishan Town,Nanhai District,Foshan City,Guangdong Province,China

We chat