Email: fern@hotechmachinery.com Tel: +86 13622727078

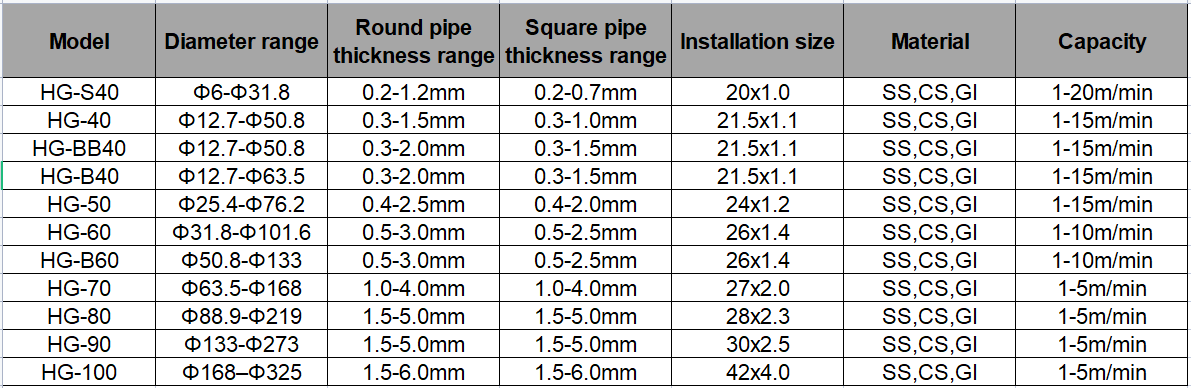

Stainless steel Decorative Pipe Making Machine is design to produce welded round tubes/square tubes,with diameter 4.8mm-325mm,thickness 0.2mm-6.0mm. The tube mill is newly design based on proactical producing and acquiring the advantages of equipment Taiwan design, which is also convenient in operation and maintenance. Brand: HOTECH Payment:T/T, L/C at sight Product Origin: Foshan, China Lead Time:60 days

Steel Pipe/Tube Making Machine can produce steel pipe/tube with ss materials and ms, gi materials such as 316, 304, 409, 3201, 202, Q235. ERW pipe mill is W forming, in the welding section we will weld the pipe.

Stainless Steel Tube/Pipe Making Machine use to produce Furniture tube such as chair foot, table foot etc. Construction tube such as Hand railing, Building support tube, Water tube, Chimney tube, Door tube; Industrial tube such as Exhaust tube, NB tube, Condenser pipe, Sanitary tube etc.

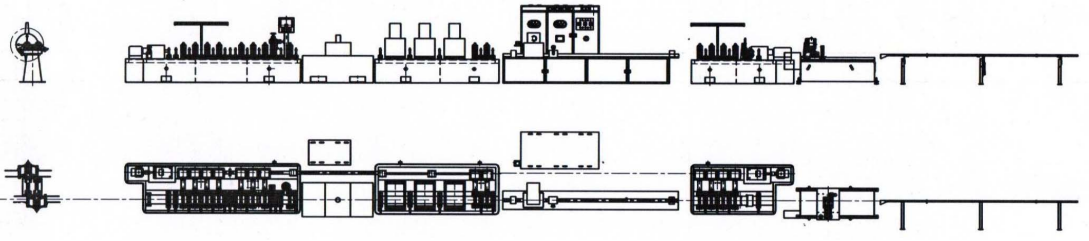

Machine Processing: Un-coiler→ Forming Section→ Welding Section→ Grinding Section→ Sizing & Straightening Section→ Cutting Section→ Run out table

| Machine Paramter | |

| Major motor | Siemens |

| Reducer | NJ130 or Dongfeng 145 |

| Cutting machine | Abrasive Cutting Machine or Metal saw cutting machine |

| Welding device | Included |

| Machine base | Q235 materials |

| Machine shaft | 40Cr |

| Machine arrangement | 3-3-1-4 or 4-4-1-4 |

| Customized Design | |

| PLC control system | Optional |

| Roller bearing standd design | Optional |

| Grinding section | Manual / Semi-automatic / Fully automatic |

| Double Motor | Optional |

| PLC control cutting machine-cut short pipe below 1 meter | Optional |

| Double acting system | Optional |

| Online inside bead rolling machine | Optional |

| Online bright annealing machine | Optional |

| After Sale Service | |

| Warranty time | 1 year |

| Installation service | 15 years experience engineer base on salary |

| Factory layout drawing | Provide |

| Return visit service | 2-3 times per month |

| Field visit service | 2-3 times for mature market |

- The whole machine is welded by Q235 steel plate, world's top five hundred BAOSTEEL material, machine vibration aging treatment.

- Follow Taiwan technology, provide stable structure design.

- All the key parts are processing by CNC machine centre to ensure the precision of equipment .

- Adopt NJ130/Dong Feng auto transmission, enhanced turbine gearboxes, ensure stability of transmission system.

- ERW tube mill can be customized by customer's requirements.

Handrails are corrosion and heat resistant iron-based alloy containing at least 16% chromium, along with nickel and other alloy elements. Stainless steel is grouped into numbers 200, 300, and 400.

The stainless used for railing systems and other architectural applications is typically grade 304 and 316. Both grades are available in 304 pipe and tubing. The most economical form of stainless railing systems is welded tubing and is typically non-annealed, non-pickled, and non-pressure tested.

This product is ASTM A554 (Welded Stainless Steel mechanical Tubing) is available in the same OD as stainless pipe, but can be had at a lower cost.

1. Seamless Steel Tubes: Craft precision seamless steel tubes with exceptional quality, catering to diverse industries such as automotive, construction, and engineering.

2. Structural Innovations: Engineer innovative structural components, confident in the integrity and strength of tubes produced by Hotech ERW pipe plant.

3. Industrial Pipelines: Contribute to the development of efficient industrial pipelines, relying on the consistent excellence delivered by tube manufacturing machines.

4. Architectural Brilliance: Elevate architectural designs with stainless steel railing systems crafted from tubes produced by ERW mill. The resulting blend of form and function is unparalleled.

Key words: tube making machine, pipe making machine, industrial tube mill, decorative tube production line, welded tube making machine, ss tube mill, ss pipe mill, erw tube making machine, erw pipe mill

Tube mirror polishing machines utilize a combina

Tube forming machines are essential equipment in

Seamless pipe is manufactured by extruding the m

Contact: Fern Li

Phone: +86 13622727078

Tel: +86 13622727078

Email: fern@hotechmachinery.com

Add: Shishan Town,Nanhai District,Foshan City,Guangdong Province,China

We chat