Email: fern@hotechmachinery.com Tel: +86 13622727078

Welded stainless steel welded pipe refers to a steel pipe with seams on the surface that is welded after bending and deforming a steel strip or steel plate into a circular, square, etc. shape.

1. According to the use, the welded stainless steel welded pipe has general use and high temperature and high pressure. The latter pipe is often a special alloy steel. The problem of shortening cracks in the welding seam and the heat-affected zone pipe machinery must be considered and dealt with. The performance will not change too much due to the influence of welding operations.

2. According to the thickness of the pipe wall, pipes made of relatively thin materials such as steel strips can be welded with high frequency, and some thin-walled pipes can be welded with shielding gas; pipes with a wall thickness exceeding 2mm can be welded by hand arc welding.

3. According to the diameter of the pipe, it can only be welded on one side with a small diameter and can be welded on both sides by a technician who can drill into the pipe.

One-sided welding puts forward requirements on the skills of welders. One-sided welding can be done by two people. Through the steel ball test, it is ensured that the passing capacity of the cross-sectional area and the shape of the weld meet the planning requirements.

4. As long as the pipe material is high-strength alloy steel, including temperature-resistant, pressure-resistant, wear-resistant, and low-temperature resistant alloy steel pipes, it is necessary to focus on the implementation of the welding process to avoid martensitic arrangements and cracks due to high-temperature welding operations The general requirement of the process is that the welding rod should be selected well.

And it is baked and sent to the welders for use according to the requirements. Before welding, the two ends of the weld should be cleaned of oil, water, rust and debris, and the energy of the welding line should be as small as possible. The placement of seams has an annealing effect on the heat-affected zone as much as possible. Cool slowly after welding, cover with asbestos cloth, etc.

5. In order to ensure the welding quality of the pipes, the welders must practice and take exams to be qualified. In order to weld the steel pipe well, the welder must consider the operation skills in addition to the basic theory. The welding process of the pipe may include several postures such as downward welding, vertical welding and overhead welding (when the pipe cannot be rolled). The forming of welding and overhead welding (some pipes are not very large, one-time forming, and the current cannot be adjusted halfway), control the stability and forming of the arc during the process, and shake it properly, and combine the forming and necessary shaking.

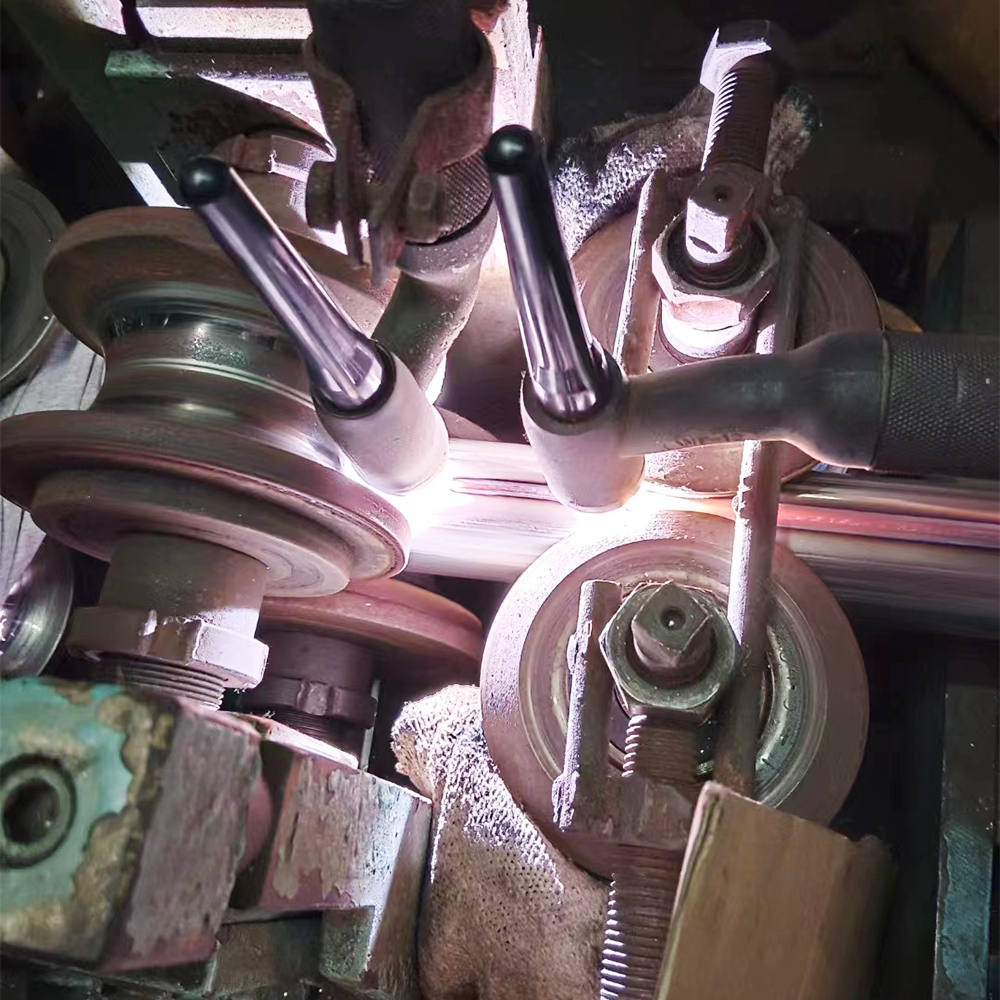

Tube mirror polishing machines utilize a combina

Tube forming machines are essential equipment in

Seamless pipe is manufactured by extruding the m

Contact: Fern Li

Phone: +86 13622727078

Tel: +86 13622727078

Email: fern@hotechmachinery.com

Add: Shishan Town,Nanhai District,Foshan City,Guangdong Province,China

We chat