Email: fern@hotechmachinery.com Tel: +86 13622727078

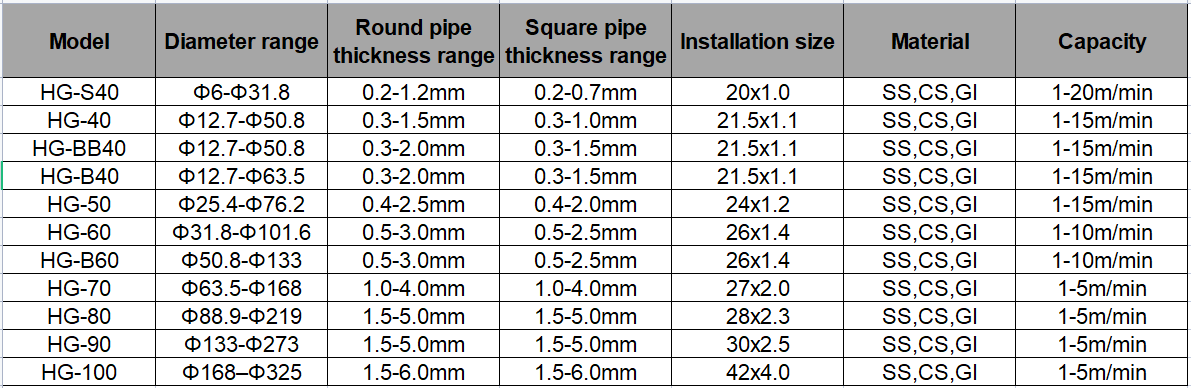

Stainless steel Industrial Pipe Making Machine is design to produce welded round tubes/square tubes,with diameter 4.8mm-325mm,thickness 0.2mm-10mm. The tube mill is newly design based on proactical producing and acquiring the advantages of equipment Taiwan design, which is also convenient in operation and maintenance. Brand: HOTECH Payment:T/T, L/C at sight Shipping Port: Foshan , China Lead Time:60 Days

Stainless steel tube mill is a technologically advanced facility designed to produce high-quality stainless steel tubes with exceptional precision and efficiency. We combine the latest advancements in metallurgy, engineering, and automation to deliver tubes that meet the most stringent requirements of various industries.

Industrial tubes are used in the manufacturing of various automotive components, such as exhaust systems, fuel lines, brake lines, and suspension components.

Also can used for oil and gas industry for drilling, extraction, and transportation of oil and gas. They are used for manufacturing pipelines, drilling casings, and other components.

Machine Processing: Un-coiler→ Forming Section→ Welding Section→ Grinding Section→ Sizing & Straightening Section→ Cutting Section→ Run out table

| Machine Paramter | |

| Major motor | Siemens |

| Reducer | NJ130 or Dongfeng 145 |

| Cutting machine | Metal saw cutting machine |

| Welding device | Included |

| Machine base | Q235 materials |

| Machine shaft | 40Cr |

| Machine arrangement | 4-4-1-2-5 |

| Customized Design | |

| PLC control system | Optional |

| Roller bearing standd design | Optional |

| Grinding section | Manual / Semi-automatic / Fully automatic |

| Double Motor | Optional |

| PLC control cutting machine-cut short pipe below 1 meter | Optional |

| Double acting system | Optional |

| Online inside bead rolling machine | Optional |

| Online bright annealing machine | Optional |

| After Sale Service | |

| Warranty time | 1 year |

| Installation service | 15 years experience engineer base on salary |

| Factory layout drawing | Provide |

| Return visit service | 2-3 times per month |

| Field visit service | 2-3 times for mature market |

Steel Pipe Tube Forming Machine characteristic:

1. The whole Stainless Steel Tube Forming Machine is welded by Q235 steel plate, world's top five hundred BAOSTEEL material ,machine vibration aging treatment.

2. Follow Taiwan technology, provide stable structure design.

3. All the key parts are processing by CNC machine centre to ensure the precision of equipment .

4. Adopt NJ130/Dong Feng auto transmission ,enhanced turbine gearboxes ,ensure stability of transmission system.

5. Tube Production machinery can be customized by customer's requirements.

Nominal Bore

Nominal Bore(NB) is the European designation equivalent to NPS is DN(diametre nominal/nominal diameter /Durchmesser nachNorm), in which sizes are measured in millimeters.NB is also frequently used interchangeably with NPS.

Nominal Pipe Size (NPS) is a North American set of standard sizes for pipes and fittings used for high or low pressures and temperatures. Fipe size is specifid with two non -dimensional numbers: a nominal pipe size (NPS) for diameter based on inches and aschedule (Sched.or Sch.) for wall thickness.

The name NPS is based on the earier lron Pipe Size (IPS) system That IPS system was established to designate the pipe size. The sizerepresented the approximate inside diameter of the pipe in inches An IPS 6" pipe is one whose inside diameter is approximately 6inches Users started to call the pipe as 2inch, 4inch, 6inch pipe and so on.To begin, each pipe size was produced to have one thicknesswhich later was termed as standard (STD) or standard weight (STD.WT).The outside diameter of the pipe was standardized.

As the industrial requirements handling higher pressure fluids pipes were manufactured with thicker walls, which has become knownas an extra strong (XS) or extra heavy (XH). The higher pressure requirements increased further ,with thicker wall pipes.Accordingly,pipes were made with double extra strong (XXS) or double extra heavy (XXH) walls, while the standardized outside diameters areunchanged. Note that on this website only terms XS and XxS are used.

Stainless Steel Tube Mill Advantages

1. Precision Manufacturing: Our SS tube mill is equipped with advanced machinery that ensures precise control over tube dimensions, wall thickness, and surface finish. This results in tubes that meet the highest standards of accuracy and quality.

2. Versatile Capabilities: Hotech pipe forming machine can produce stainless steel tubes in a wide range of sizes, from small-diameter tubes for intricate applications to large-diameter pipes for heavy-duty industries. We offer flexibility in terms of tube sizes, thicknesses, and grades, catering to diverse project requirements.

3. Innovative Technologies: We are at the forefront of innovation in the pipe manufacturing industry. Our tube mill incorporates cutting-edge technologies, such as automated controls, advanced welding techniques, and real-time monitoring systems, to enhance productivity, efficiency, and overall performance.

4. Seamless Integration: As a professional SS tube mill supplier, we understand the importance of integrating our tube mill seamlessly into your existing production line. Our tube forming equipment is designed for easy integration and can be customized to fit your specific requirements. We provide expert guidance and support throughout the integration process to ensure a smooth transition.

5. Operational Excellence: SS pipe mill is designed for optimal performance and operational efficiency. We prioritize ease of operation, maintenance, and troubleshooting to minimize downtime and maximize productivity. With our equipment, you can achieve high throughput and consistent tube quality.

Container Shipment

Key words: tube making machine, pipe making machine, industrial tube mill, decorative tube production line, welded tube making machine, ss tube mill, ss pipe mill

Tube mirror polishing machines utilize a combina

Tube forming machines are essential equipment in

Seamless pipe is manufactured by extruding the m

Contact: Fern Li

Phone: +86 13622727078

Tel: +86 13622727078

Email: fern@hotechmachinery.com

Add: Shishan Town,Nanhai District,Foshan City,Guangdong Province,China

We chat